Inquiry basket

Inquiry basket

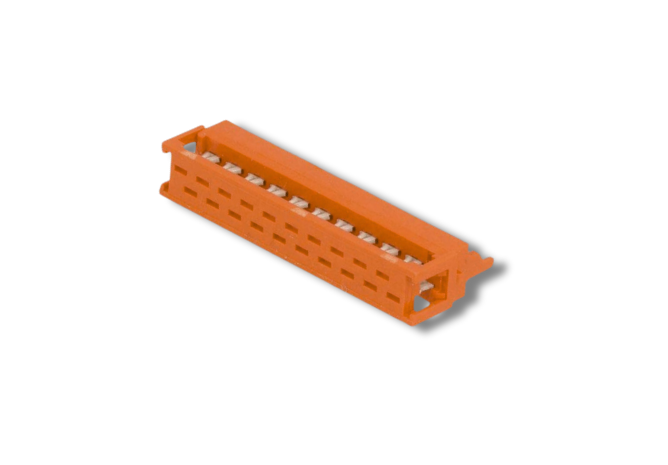

TE Connectivity's (TE) Micro-MaTch Cable Assemblies provide reliable connections in high-vibration environments and use a spring-design contact to prevent fretting corrosion. Relative movements caused by vibrations/thermal expansion between male and female contacts are absorbed by an additional positioning spring in the female part. By preventing movements on the contact spot, a gas-tight connection can make the Micro-MaTch contact spring system fretting corrosion resistant. These TE cable assemblies are available from 4 to 20 positions and in 7.5cm to 20cm (0.246-foot to 0.656-foot) standard lengths. Applications include production and material handling equipment, control units, robots and motors, and central heating units, and car radios.